One Stop Fabrication Manufacturer Automobile Board to Board Connectors

Description

Basic Info.

| Mated Height | 2.50 - 9.60mm |

| Impedance | 85-100 Ohms |

| Circuit | 4-24 |

| Housing | Nylon |

| Terminal Structure | Terminal Under the Premium |

| Terminal Material | Copper Alloy |

| Mould Leadtime | Within 21 Working Days |

| Batch Leadtime | Within 10 Working Day Per Lot |

| Sample Lead Time | Within 5 Working Days When Mould Finished |

| Drawing Format | Igs,STP,X_T,Dwg,etc. |

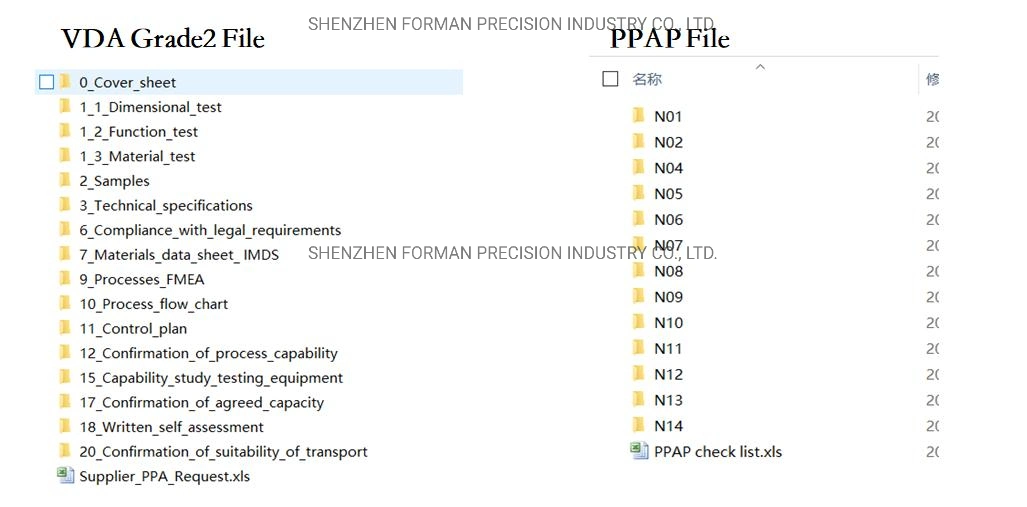

| ISO&IATF Certification | Yes,We Have. |

| Quality Assurance | 100% CCD Inspection and Spot Check |

| ERP System | Yes |

| Nda | Available to Sign Before Inquiry |

| Testing Laboratory | Yes |

| Halogen-Free | Yes |

| Tolerance | +/-0.05~+/-0.015mm |

| R&D Capacity | Yes |

| Material | Plastic + Copper |

| Process | Plastic Molding Injection and Stamping Terminal |

| Item | Automobile Board to Board Connectors |

| Transport Package | Tray + Carton |

| Specification | Custom |

| Trademark | Custom |

| Origin | Shenzhen |

| Production Capacity | 5, 000PCS/Day |

Product Description

One stop fabrication manufacturer Automobile board to board connectorsForman has been fabricating electronics components since 1999 and we offer one-stop services from design concept, mold manufacture, plastic injection, metal stamping, and final assembly services.

Product Description

Product Design Specification

| Product Description | Customized automotive/automobile electric connector components |

| Material Option | Insulator Housing: PBT, LCP, PA66, PA66+glass fiber 30%, PA9T, etc. Contact Terminal: C7025, C5191, C2680, H65, etc. Ground lug: C5191, C2680, etc. |

| Plating Option | High Temperature Matt Tin Plating Over Nickel, Gold plating on contact area, tin plating on soldring area, etc. |

| Product Assembly Method | Automatic Pin/Terminal Inserting Method or Injection molding terminal/pin |

| Product Application | Automotive OBD Moudle, PCB board pin panel for window lifting system, Wireless Charging, etc. |

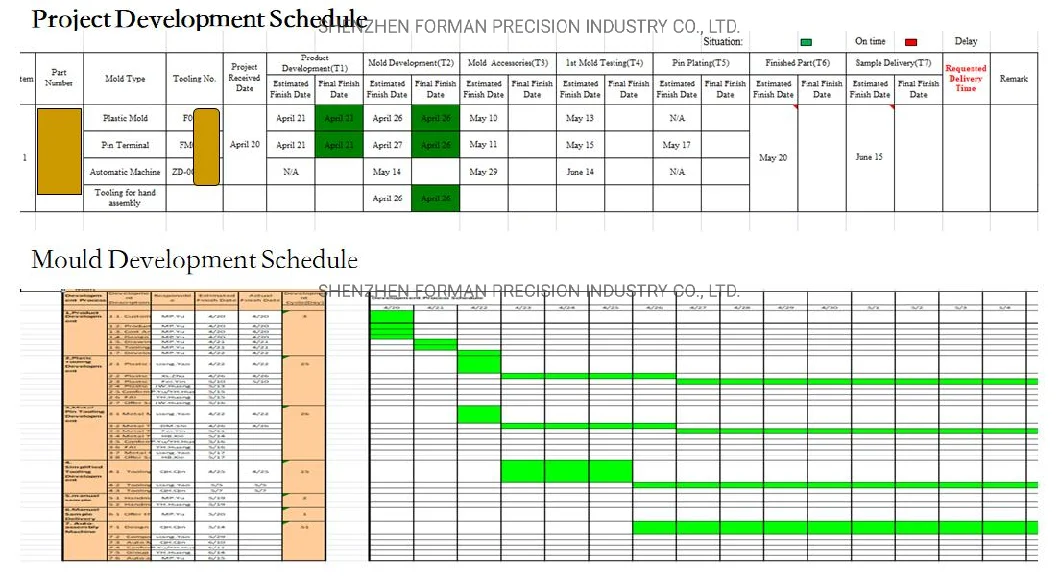

| Product Development Schedule | 30 Days for the mould making and first prototype + 30 Days for PPAP document and testing. The first batch will take 10~15 working days and the further will only take 7 working days. |

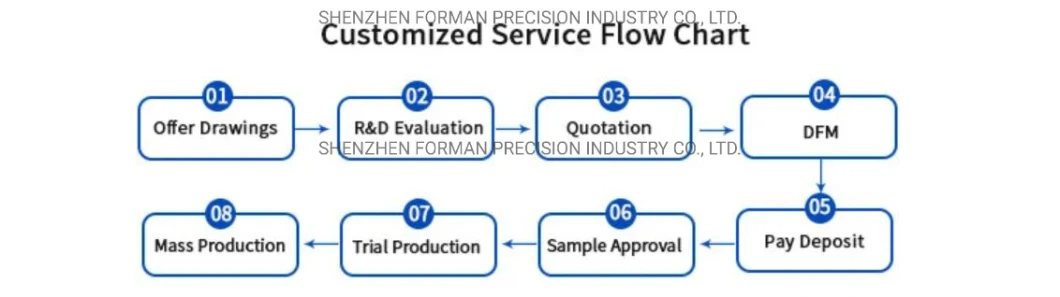

Product Sample Range Development Flow

Product Evaluation Process

Evaluation Details

Shenzhen Forman Precision Industry Co., Ltd(Abbreviation FPIC) has always been committed to the research, development and manufacture of OEM automotive components, energy storage connectors, electronic connectors, wire harnesses, thermal modules, plastic parts and metal parts since 1999. FPIC has been attaching importance to scientific production and efficient quality control, we have introduced the ISO9001, ISO14001, and IATF16949 management systems, also the ERP and MES production control systems. Nowadays, we have our own R&D Center, Testing Center, and Production Departments for Mould-Making, Injection Molding, Stamping, and Assembly. Insisting on the philosophy of "Focus on Customer, Contributor Based, and Always Going All Out", FPIC offers good quality controlling capability, super flexible delivery, and continuous cost optimization, we look forward to working together with you for mutual development and benefits.

| Total Employee | More than 200 people |

| Services | Design concepts, Plastic injection, Metal Stamping, and Assembly |

| R&D Team | Yes, there are 30 engineers in our R&D department and all of them are studied the related profession with rich experience in electronics. |

| Operation System | ERP |

| Quality Assurance | 100% CCD quality inspection and spot check by our QC team. We have a strict quality management system from raw material to final products, also there is a professional Laboratory in our factory to finish most kinds of tests. |

| Our Advantage: | 1:Strong Full-Auto Production Competence 2:100% Quality Inspection from raw material to finish products. 3:Over 20 years of manufacturing experience and our capital of more than RMB50,000,000 4:All of our employees must finish operation training class before running into production and each month we will have a new training class to improve skills, teach them safe operation and so on. 5:Forman has passed ISO9001, ISO14001, and IATF16949 Certificates, all our operations meet Chinese Politics and Environment Protections. |

Plant Details Production Area

Workshop Display:

Production Capacity

Material Tracking

Every material will post a label when it's finished, it's easy for us to see the part number, material, qty, date, and other information.Process inspection

We verify the material reliability in the designing stage, then control every process will strictly comply with all quality systems for best quality in production.

Testing Center

Forman clearly understands the quality importance for a company, therefore, every aspect from product designing, producing, to inspecting has been paid attention to.

Testing Equipment List

FAQ:

Q: Where is your factory and do you have any certificates? A: Our factory is located in Gongming town, Shenzhen and we have passed ISO9001, ISO14000 and TS16949Q: Do you have any qty limited? A: Firstly for our stock products, we can arrange the shipment according to your requirement and for the specialized one, it depends on the production cost

Q: Can you please talk about your quality assurance? A: FPI completely controls the income and outcome material according to the ISO system and 100% check for our parts by instrument, QC will spot check in each process at least per 2 hours, and before shipment, our OQC will arrange the inspection again

Q: What's kinds of information you need for a quote? A: In order to quote for you earlier, please provide us the details together with your inquiry. 1. 3D drawings (STEP, CAD, SOLID Works, PROE, DXF and PDF) 2. Material requirement (include contact material and insulation material.) 3. Surface treatment 4. Quantity or Consumption (per order/ per month/ annual) 5. Any special demands or requirements, such as packing, labels, delivery, etc.

Forman warmly welcomes your inquiry and visit for more details and information.

Our Contact